TeXtreme® Spread Tow Thin-Ply Technology

Carbon Fiber Solutions by TeXtreme®

TeXtreme® is a high-performance Spread Tow Thin-Ply Technology developed to meet the most advanced structural demands in composites. Through precise spreading, alignment, and weaving of fibers, TeXtreme® enables ultra-light, ultra-strong reinforcements with superior surface quality and mechanical performance.

Compared to conventional carbon reinforcements, TeXtreme® materials are thinner, flatter, and more consistent, delivering distinct advantages in stiffness, damage tolerance, and production efficiency.

Fundamental Components of the TeXtreme® Technology

The components of TeXtreme® Spread Tow Thin-Ply Technology work together to deliver lightweight strength, enhanced durability, and maximum material efficiency.

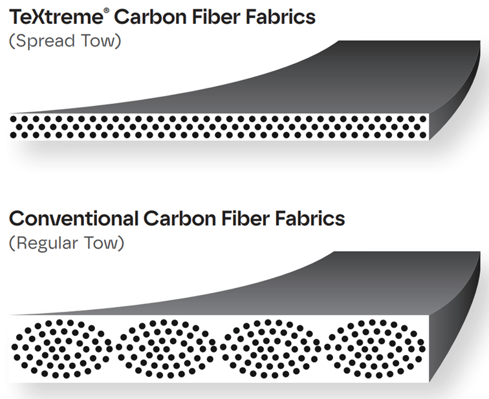

Spread Tow

Fibers are spread into wide, flat tapes to eliminate crimp and resin-rich zones. This enables higher fiber alignment and more uniform material distribution, which provides the foundation for structurally efficient composites.

Thin-Ply

Ultra-thin reinforcement layers below 0.05 mm allow precise control of fiber orientation and stacking. This opens up new possibilities in laminate design, enabling tailored mechanical responses and reduced thickness.

Tailored Tape Weaving

Spread Tow tapes are woven in customized patterns that maintain fiber orientation and minimize distortion. This ensures consistent structural properties and supports the creation of symmetrical layups in multiple directions.

TeXtreme® vs Conventional Carbon

TeXtreme® Spread Tow architecture transforms the internal structure of composite reinforcements, minimizing fiber waviness and reducing gaps between tows. The result is a more uniform laminate with improved fiber packing, better load transfer, and enhanced mechanical response. Reduced crimp and fewer resin pockets support weight reduction, precision layups, and optimized material usage, making it ideal for performance-driven applications where every gram matters.

TeXtreme® vs Conventional Carbon: By the Numbers

Weight reduction.

Fewer crimp points.

Higher tensile strenght.

Real-World Success Stories

TeXtreme® Spread Tow Thin-Ply Technology is trusted by leading brands across aerospace, automotive, sports, and industrial sectors. Its ability to deliver ultra-light, high-strength composite reinforcements with exceptional structural precision has made it a key enabler of performance in some of the world’s most demanding applications.

Blackwing Raises the Standard in Ultralight Aviation

A visionary approach to aviation, combining lightweight carbon fiber engineering, speed, and safety with Scandinavian design excellence. Precision-built in Sweden, Blackwing aircraft set a new benchmark for performance and the pure joy of flying.

Inside the Zephir Project

An ambitious venture pushing the boundaries of sailing performance through speed, precision, and sustainability. Cutting-edge design and lightweight construction drive a new course in marine technology.

Breaking New Ground with Elytron Aeronautica

A bold mission reshaping the future of UAV performance with unmatched endurance, payload capacity, and precision. Advanced composites and cutting-edge engineering enable lighter, stronger, and smarter airframes, setting a new standard in aerospace technology.

Fischer Hockey Redefines Lightweight Performance on Ice

A bold leap forward in ice hockey innovation, blending TeXtreme® with Fischer’s century of craftsmanship. The result: ultralight sticks engineered for explosive power, precision control, and lasting durability. Trusted by professionals and ambitious players worldwide.

Ready to Use TeXtreme®?

Unlock the full potential of TeXtreme® Spread Tow Thin-Ply Technology in your application. Our engineers and composite experts are here to help you optimize performance, reduce weight, and streamline your manufacturing with precision-tailored solutions.