Aerospace

TeXtreme® for Aerospace

Reducing weight, enhancing performance, and thriving in the most extreme aerospace environments

Your Advanced Composite Partner

After more than 15 years of collaboration with aerospace companies and research partners, TeXtreme® has built leading expertise in thin plies, spread tows and advanced fiber architectures. We support your project from concept to final product.

Our network includes AS9100 certified partners for prepregs, resin systems and composite part manufacturing, ensuring full compliance with aerospace quality requirements. Whether you are designing lightweight structural parts, interior components or cryogenic tanks, we deliver material solutions with documented reliability and traceability.

The technology also supports long term sustainability goals. Weight and material reductions help lower emissions, increase fuel efficiency and extend product lifecycles across aerospace applications, all without compromising strength.

Proven Performance with Spread Tow Thin-Ply Technology

TeXtreme® reinforcements deliver measurable advantages in real-world applications, from weight savings and production scale to aerospace-proven reliability. Discover the data that drives performance.

Weight reduction compared to conventional carbon fiber materials.

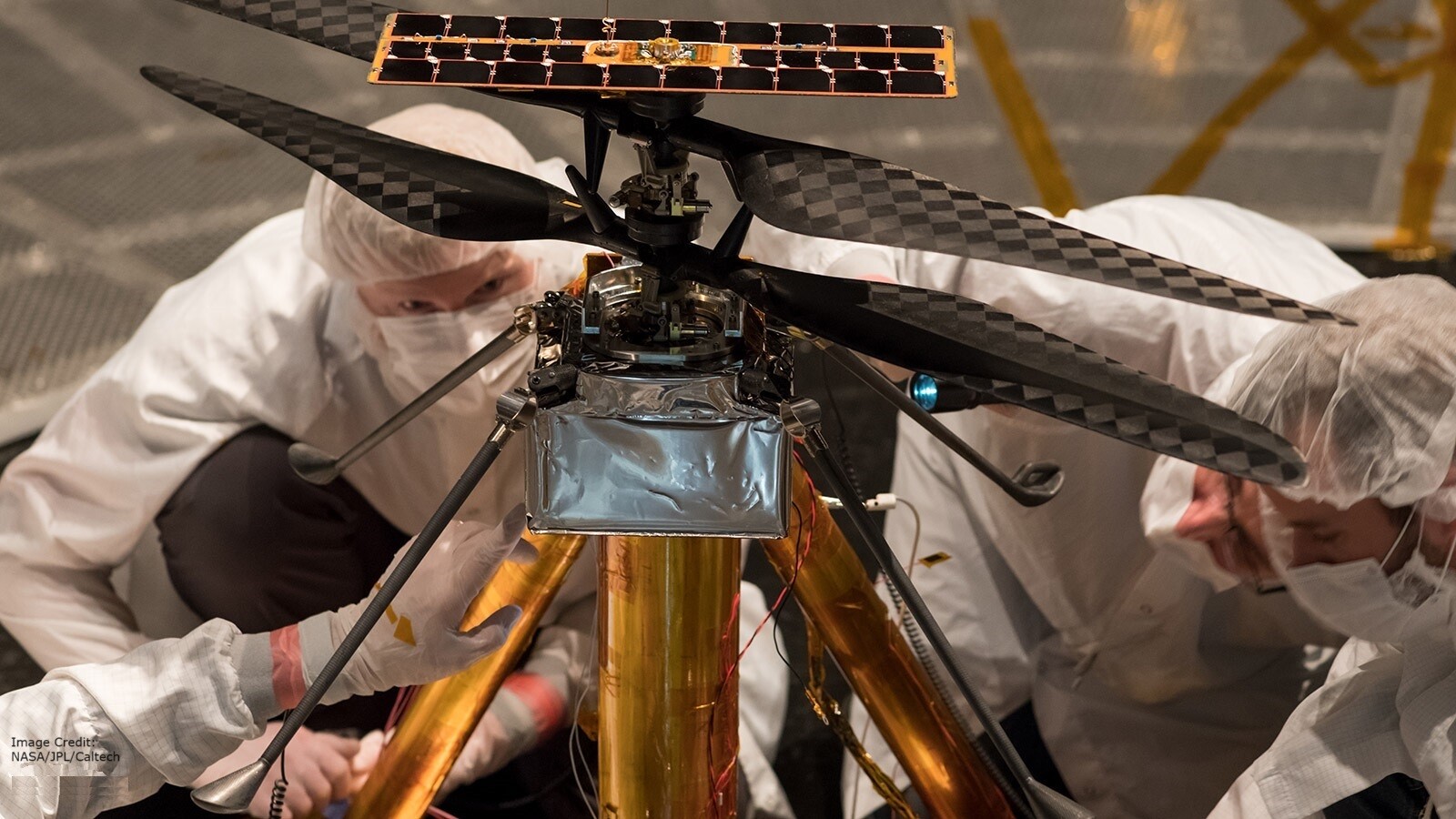

Mars helicopter. Integral parts of NASA's Ingenuity helicopter were made from TeXtreme carbon fiber reinforcements.

Filaments per tow, which guarantee availability for extensive volume applications.

Years in business. Since 2003, TeXtreme® has become a leader in lightweight composite materials.

Get in Touch

Choosing the right composite solution is critical to product performance, weight targets, and production efficiency. Our team of engineers and materials experts is ready to support your evaluation, design integration, and manufacturing process.