Article of Safety in Bikes in Composites World

13, September 2018

In the September 2018 issue from Composites World, there’s an article “Safe Cycling: Keys to Composite bike design integrity” where one of the interviewed is our Product Development Director, Fredrik Ohlsson.

“TeXtreme® spread-tow carbon fiber reinforcements from Oxeon AB (Borås, Sweden) also are being used to reduce weight and improve performance under load — especially to protect laminates from micro-cracking. Fredrik Ohlsson, product development director for Oxeon, explains: “By mixing and varying the layup sequence, by combining thicker materials (standard tow) and thinner materials (spread tow), it is possible to load a Composite in its transverse direction to a much higher degree before cracks occur in the matrix between the filaments.”

This is reportedly a great advantage in bicycles, where each push of the pedal induces a cyclic load path in multiple directions through the bike frame. Commingling TeXtreme® spread tow with Innegra’s HMPP fiber endows the part with higher elongation and ductility. “If you have a catastrophic failure of the composite part, it stays together because of the higher elongation fibers,” Ohlsson contends. “If there is a failure in a handlebar, the composite does not break completely but stays held together, minimizing the risk to hit your nose on the ground. Instead you could still maintain control of the bike until full stop.”

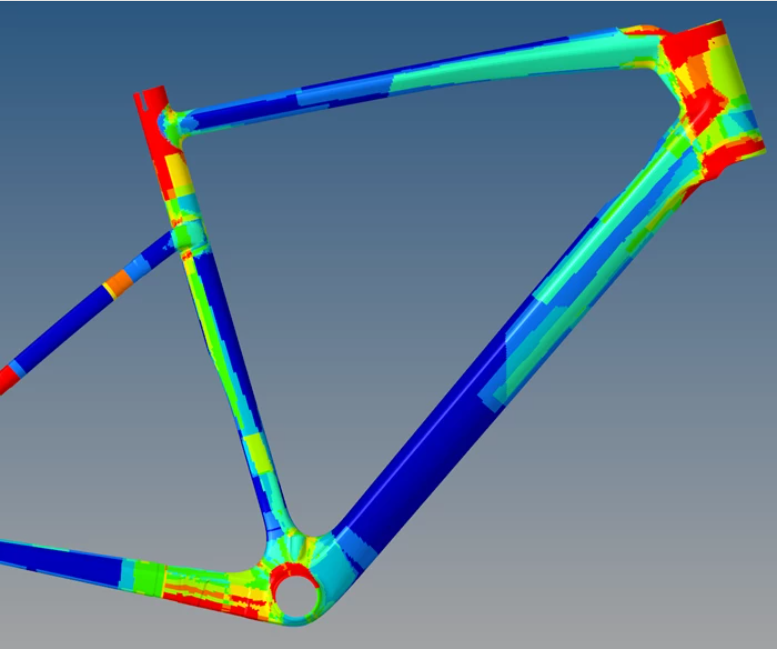

Oxeon spreads 12K (and greater) carbon tows, and reportedly can tailor biaxial or hybridized plies, or other UD or multidirectional fabric materials. The company works closely with its customers to help identify and optimize customer requirements. Ohlsson says the spread-tow fabrics also drape better than standard UD tapes around double curvatures or square shapes, yet still present the mechanical performance of cross-plied UDs. He adds, “We can tailor the fabric to change a four-ply UD layup into one fabric ply, possibly with different amounts of fiber in warp and weft, that gives exactly the requisite number of 0° and 90° fibers while still presenting a symmetrical layup.” (Fig. 5, p. 47.) TeXtreme® is used by bike manufacturer Masi Bikes (Vista, CA, US) for its new frames and forks, reducing fabric weight by 100 g/m while improving stiffness. “The goal wasn’t to just make the frame lighter, we also wanted to make it a bit smoother without giving up any drivetrain stiffness.

The material is so thin, we could work with several plies to get the same thickness or less, resulting in significant improvements,” says Masi’s product manager James Winchester. Bike gear manufacturer PRO (Eindhoven, The Netherlands) makes its PRO Vibe handlebars with the same material. Weighing 220g, PRO Vibe carbon fiber composite handlebars are now the lightest in the PRO line up, and Innegra fibers “strengthen the bar’s most vulnerable areas without compromising its weight, so your handlebar is ready to ride in the harshest conditions,” Pro states.”