Elytron Aeronautica x TeXtreme®

Elytron Aeronautica is redefining UAV performance with TeXtreme® composites, creating ultra-lightweight yet robust airframes that combine strength, precision, and adaptability for critical aerospace applications.

Taking UAV Design Further

Elytron Aeronautica is an Italian aerospace company on a mission to build smarter, stronger UAV platforms. Since 2010, the company has developed fully integrated systems from digital simulation and mold tooling to cleanroom lamination, avionics, and full-scale flight testing. Their UAVs serve civilian and institutional operators in ISR, LiDAR, SATCOM, and geophysical missions with one goal in mind: maximizing performance without compromising adaptability, stability, or field reparability.

Rather than selling individual UAV units, Elytron focuses on the industrialization of complete UAV platforms, supported by licensing agreements and technology transfer programs for international partners.

Why TeXtreme® Makes the Difference

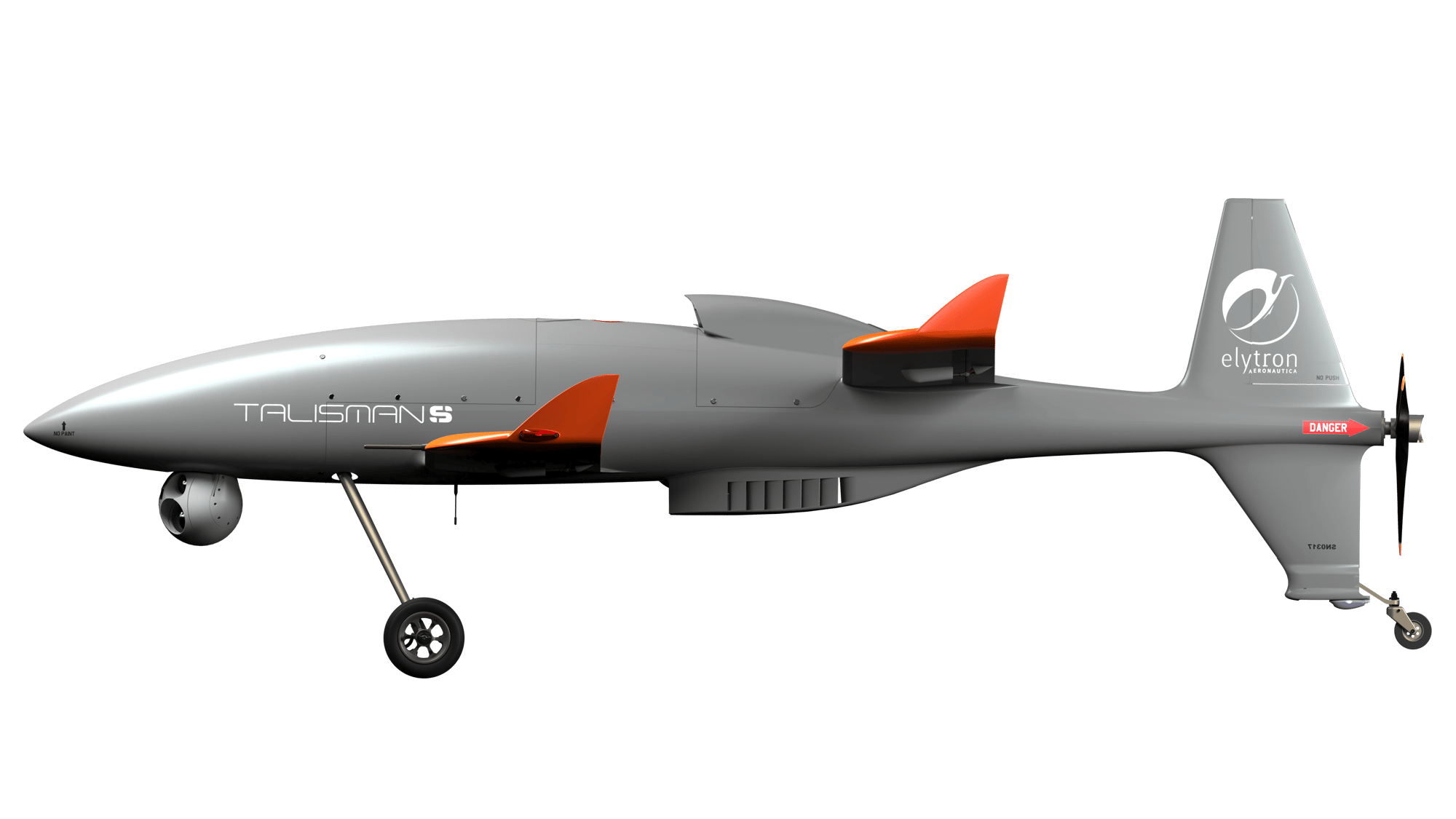

For Elytron’s flagship Talisman S60, TeXtreme® is used across all aerodynamic surfaces to deliver ultra-lightweight yet structurally robust constructions. Both 0/90 and +/–45 oriented TeXtreme® fabrics play a vital role. The 0/90 layers provide stiffness and load-bearing strength across wing skins and fuselage shells, while the +/–45 reinforcements are key in managing torsional loads and vibration in critical areas like torsion boxes and structural transitions. Together, they enable high-performance airframes that are light, rigid, and aerodynamically precise.

All TeXtreme® materials are applied using wet-on-wet vacuum lamination and cured in ovens, perfectly matching Elytron’s non-autoclave production approach. With ply thicknesses between 39 and 74.5 microns, the laminates achieve high fiber volume with minimal crimp, resulting in parts that require little to no post-processing and deliver precise fit and function.

Measurable Gains in Every Flight

TeXtreme® has helped Elytron reduce laminate thickness by up to 25 percent and total structural weight by 6 to 8 percent. For the Talisman S60, that means 25 extra minutes of flight time and 1.5 kilograms of added payload capacity. Improved damping, especially around sensitive EO/IR and LiDAR payloads, ensures cleaner data and sharper imaging. With cleaner resin distribution and symmetrical part geometry, maintenance and part reuse have also become more efficient.

Users report higher image stability, better performance under stress, and a more optimized mission-to-weight ratio. These gains translate directly into greater confidence and operational flexibility in real-world missions.

What's Next

Elytron is now scaling up. Certification is underway, and new models including Talisman HD, Searcher (150 kg), Explorer (700 kg), and the Orbiter HALE platform are in development. VTOL modules and satellite datalink systems will follow next, expanding range and deployment options.

On the materials side, Elytron is preparing to implement TeXtreme® in prepreg format, specifically developed for low-temperature oven curing (non-autoclave). This next step aims to further optimise process consistency, reduce cycle time, and enable even deeper integration of sensors, cabling, and damping structures directly into structural parts.

"For Elytron, TeXtreme® is more than a material. It is a long-term innovation partner, enabling smarter structural solutions across the airframe, payload interface modules, VTOL arms, and EMI shielding zones. Together, we are pushing the boundaries of high-performance UAV design."

Get in Touch

Choosing the right composite solution is critical to product performance, weight targets, and production efficiency. Our team of engineers and materials experts is ready to support your evaluation, design integration, and manufacturing process.